The counterweight of a counterbalance forklift is based on the point where the front wheels contact the ground. Its purpose is to ensure that the forks can lift the corresponding load, while also maintaining sufficient adhesion between the rear wheels of the forklift and the ground to enable the forklift to turn normally. The counterweight block placed at the rear of the forklift is called the counterweight of the forklift.

Moreover, there is a close relationship between the counterweight of a forklift and the bridge load rate of a counterbalanced forklift. The bridge load rate is the ratio of the bridge load (front bridge load and rear bridge load) to the total weight of the forklift, and it is also one of the important parameters of a counterbalanced forklift. It has a significant impact on the stability, traction, and power performance of the forklift's counterweight. The size of the forklift's counterweight directly affects the load distribution rate and also determines the total weight of the entire vehicle. An ideal bridge load rate not only can change the comprehensive mechanical performance of the entire vehicle, but also can enable the counterweight to achieve an ideal minimum value, thereby reducing the total weight of the vehicle and achieving the goal of reducing manufacturing costs and enhancing market competitiveness.

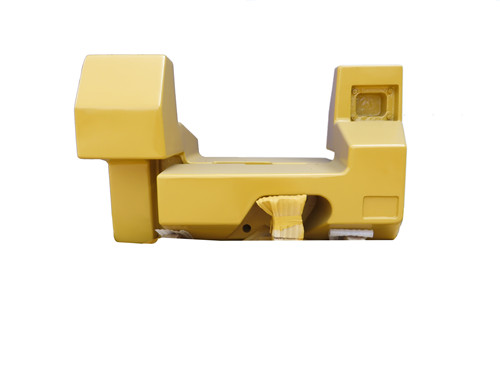

The counterweight iron is shaped based on various forms and materials. There are two types: 1. Using natural mineral sand and stones as the basic material, such as shell type, ceramic type, clay type, etc., for the counterweight types; 2. Choosing metal as the casting material, such as solid and integral counterweight iron. This is currently the common counterweight scheme. Generally, new-factory forklifts choose to use integral cast iron counterweights. Compared with other forklift components, the counterweight of the forklift can be said to have no worn-out parts.

For counterbalanced forklifts, the major characteristic is weightlessness. That is, as the height of the lifted goods increases, the load capacity decreases. For example, a 1.5-ton counterbalanced forklift cannot load 1.5 tons of goods as the height of the goods increases. The higher the height, the smaller the capacity. This should be noted when using it. The lifting height of counterbalanced forklifts is relatively lower, usually 3-5 meters are common. Additionally, its turning radius is larger than that of reach trucks. If you need to use a counterbalanced forklift for loading or replenishment operations, a wider aisle for the shelves is required.